Infusion Pumps 101

Section 1: What are infusion pumps used for?

Section 2: Infusion Pump Features & Functions

Section 3: How does an IV Pump Deliver Fluids?

Everything you need to know about infusion pumps in healthcare settings.

An infusion pump is an indispensable tool in clinical healthcare environments. The basic function of infusion pumps is to deliver, or infuse patients with accurate quantities of medicine or other fluids over a specific amount of time, either in a steady stream or structured intervals. Infusions are vital for:

- Administering pain medication

- Delivering blood

- Administering chemotherapy

- Delivering hydrating fluids or nutrients

- Delivering insulin or other hormones, antibiotics, etc.

Infusion pumps have a plethora of advantages to patients and healthcare practitioners: they have increased accuracy and safety compared to using a ‘drip’ method for IV bags, which was common practice before infusion pumps became popular. With the use of infusion pumps we now have the capability to deliver fluids in very small volumes at a super precise rate. This is crucial for the care of the smallest patients in the NICU, and for many other patients in a multitude of other settings.

Patient safety is elevated with of the use of infusion pumps because the pump can alert practitioners if there is any type of blockage or occlusion and it helps secure the IV rate and medication flow.

In most cases, you’ll find an infusion pump at the bedsides of patients in hospitals, nursing homes, and other healthcare settings where patients can receive direct care.

The most common types of infusion pumps found in all types of healthcare facilities include:

- Large Volume (LVP) Pumps: These pumps administer large doses of medications and nutrients over time using an IV/fluid bag – these pumps are most commonly used in stationary settings.

- Syringe (Small Volume) Pumps: Syringe pumps offer a great deal of control for administering pain medication and other fluids needed in small amounts. The motor pushes the syringe driver to deliver the fluid from the syringe to the patient. A very small amount of fluid can be administered over a long period of time at a consistent rate.

- Ambulatory Pumps: Portable or wearable pumps, able to deliver a large range of medication in mobile or shifting settings.

- Patient-Controlled Analgesia (PCA): A pump attached to the IV lets patients release pain medicine by pressing a handheld button (sometimes referred to as a bolus cable). This method is set up to release smaller doses of pain medication more often, so the patient can have more control over pain relief.

-

Smart Pumps: Smart pumps are growing more and more popular in healthcare settings today; these pumps are far more complex and technologically capable, with network connectivity and built-in software. The software features vary on each pump and can be adjusted to the organization/facility and in most-cases, store a drug library. The healthcare team at that facility is then able to input drug specifications such as concentration, volume, and rate/duration of fluid delivery depending on drug details and patient information. Smart pumps also have Software systems built-in to prevent errors and protect the patients. These systems will help clinicians avoid mistakes when programming the pump and will send real-time alerts when identifying something inaccurate or detecting a problem. To learn more about smart pumps and view statistics on their efficacy, visit this study by the Institute for Safe Medication Practices.

*all infusion pumps, depending on manufacturer and era, have the ability to be either mechanical or electronic, though most are electronic that you will see in healthcare settings today.

Since infusion pumps are so diverse in function, they also face their own set of challenges. They need to be used, maintained, and stored carefully to prevent physical damage to the unit.

According to the Food and Drug Administration (FDA), they're susceptible to:

Software issues:

Error messages and cybersecurity threats can lead to issues for the actual software built into a pump. Standardization of software and controls has also been a rising challenge in the past few years. Lack of consistency in terminology and location of functions across different pump models can lead to improper use and more user errors.

Alarm errors:

In the event of an occlusion, or other safety hazards detected by the pump, the pump may not sound an audible alarm, resulting in a hazard for the patient.

Broken parts:

Physical damage such as cracks or water damage can cause an infusion pump to function improperly, leading to under-infusion or over-infusion. It is important to inspect pumps regularly for physical damage that can sometimes go undetected, due overuse or miniscule cracks in hard-to-see areas.

Battery failures:

This is sometimes caused by overheating of the battery. In other circumstances, the battery of the pump was not maintained properly or on time.

Fire, charring, spark, or shocks:

This can be caused by overheating or improper use.

Since these pumps are unique in both design and functions, they should be operated and if needed, repaired, by trained technicians who possess a thorough understanding of the pump’s built-in software and physical designs.

To learn more about infusion pumps or infusion pump repair services, get in touch with AIV.

Everything you need to know about the features and parts of an infusion pump and how they work.

Infusion pumps are invaluable in healthcare settings. They allow healthcare practitioners to provide care for a greater volume of patients than they otherwise could, with a higher degree of accuracy. Use of infusion pumps also provides a greater quality of care in non-contact settings. This is essential to ensure safety for health professionals when considering pandemic restrictions and spacing protocol.

Infusion pumps are both complex and simple, using multiple design and programmable features to carry out personalized infusion procedures.

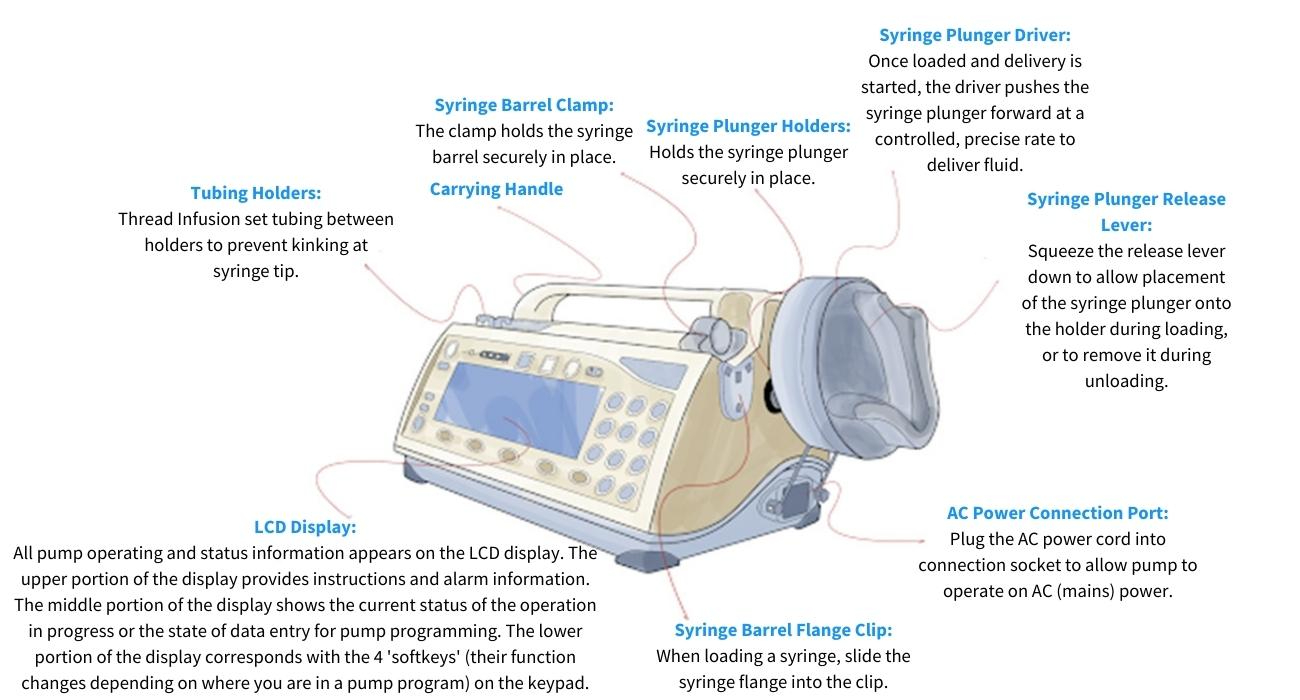

Let’s take a deeper look at some of the features and parts of an infusion pump:

Display

The display screen and keypad on an infusion pump allows the operator to program the pump for use. They can use the screen to:

- Input or retrieve patient data

- Set the length of infusion

- Set the infusion rate

*Some newer infusion pumps are now offering a touch-screen infusion pump

Power Supply

All infusion pumps run from a power supply – most are plugged into an AC adapter in an outlet or nearby power tap, and in some cases are battery powered (ex: when a patient is being transported from one location to another. It is imperative to patient safety that the power supply for infusion pumps is stable and accessible.

AIV specializes in power supply for infusion pumps –offering AC adapters, a variety of power cords, and the PowerMATE® - a special purpose relocatable power tap that can be attached to an IV pole.

Alarms

Most infusion pumps come equipped with visible and audible alarms. These alert the operator of errors or potentially dangerous conditions that could interrupt the infusion process or harm the patient. For instance, if the tube that delivers the medication to a patient is blocked by air, the infusion pump’s alarm will go off to notify the operator of a hazard. There are also a myriad of alarms and alerts that can sometimes be difficult to pinpoint and/or fix. According to the National Library of Medicine, “the variety of alarms from all types of medical devices has increased from 6 to 40 in the last three decades”.

Expansion

Some infusion pump systems are capable of expansion where they can attach to one another for more complex infusions with multiple fluids/medications. They can connect to an ongoing infusion line; with the additional large volume pumps either connected on the side or stacked on top (see examples below).

Programmability

Smart infusion pumps can be programmed via internal software, letting operators automate intermittent or continuous infusion procedures. The pump will then dispense the fluid at the programmed rate, amount, and duration as set by the healthcare professional.

Just like computers or phones, the internal software for each model of pump can differ greatly and requires extensive training prior to use.

Compatibility

The usage of tubing for large volume pumps and syringes in small volume pumps is limited per each pump due to compatibility. In the context of syringe infusion pumps, most pumps can usually accept standard syringes, varying in size based on the manufacturer and model of the pump itself. But the size of tubing accepted by large volume or volumetric pumps is much more stringent and compatible tubing must be precise for the pump to perform with accuracy. New and compatible tubing/syringes are purchased frequently for each facility and must be sourced from a reliable seller.

Basic Functionality on how IV Pumps Work

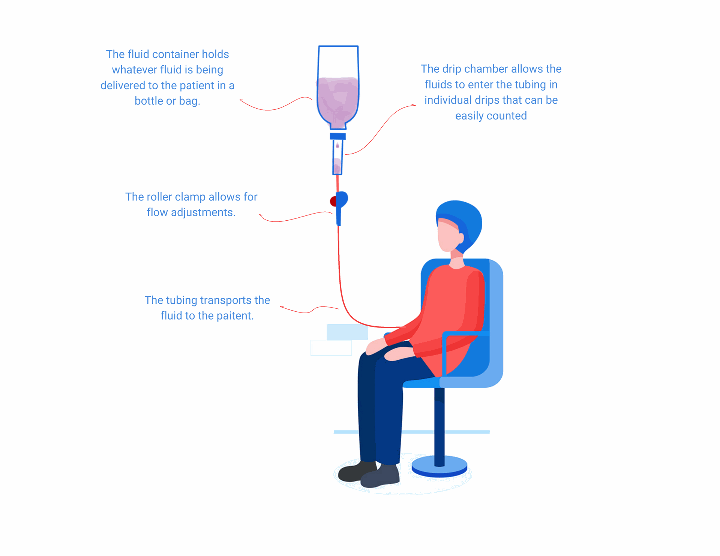

Historically, a standard gravity IV drip was used (and still is at times) to deliver fluids to patients.

This method uses the pressure of gravity to deliver medication into the IV line at a safe and steady rate. Gravity IV drips are monitored and calculated by determining the quantity of fluid needed and desired duration of time for delivery, this will establish how many drops per minute/per hour will be administered.

The classic setup broadly includes four parts (see below):

However, you’re more likely to see a large volumetric pump or a syringe pump in healthcare settings today.

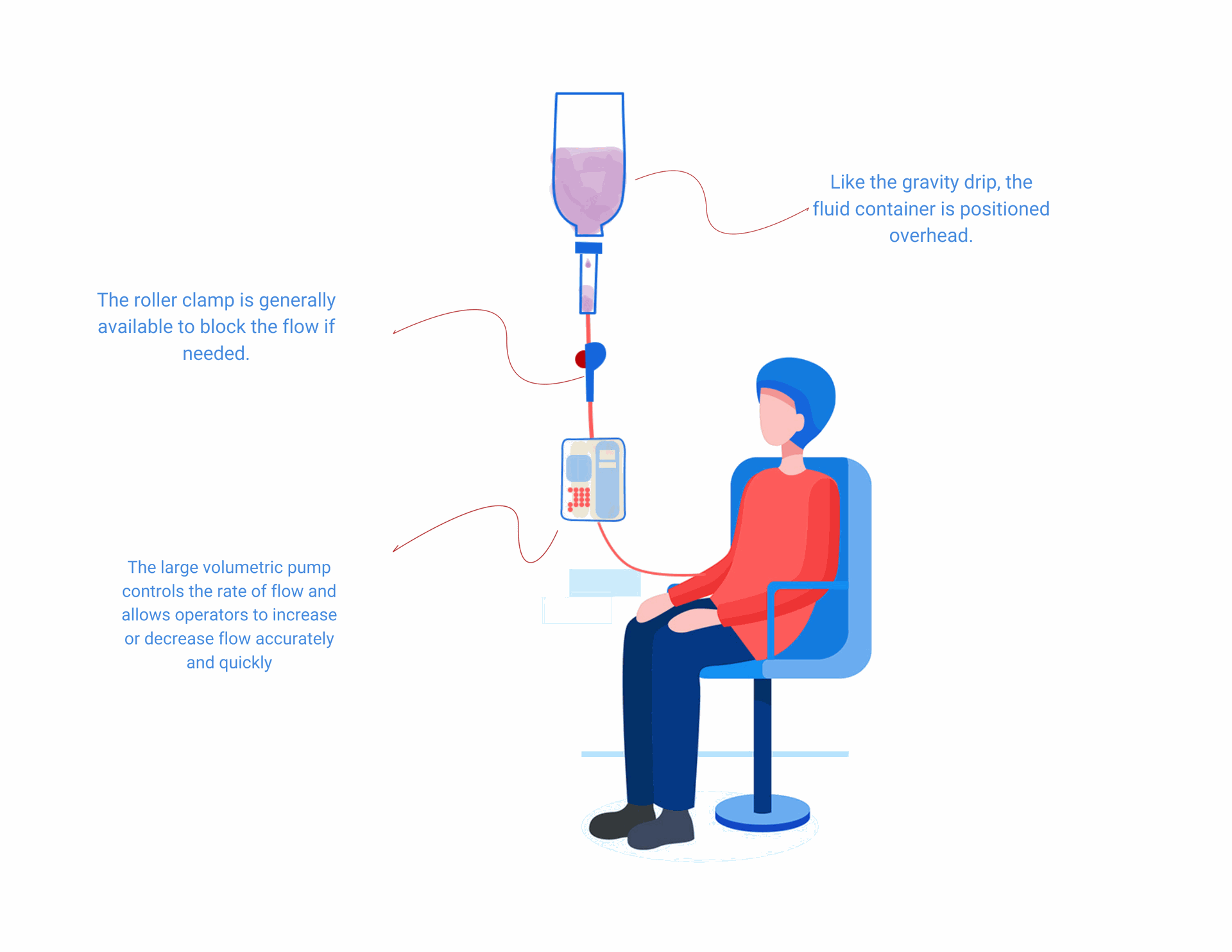

A large volumetric pump works on the same principle as the standard gravity drip, but with greater control and accountability over the flow of fluids.

For smaller patients and smaller volumes of fluids, a syringe pump is the preferred choice – this set up is very similar but with the pump intercepting the fluids from the IV bag and regulating the timing and rate before it reaches the patient (see below).

The syringe pump tightly controls the volume of fluid entering the patient by managing the rate of “siphoning.” More and more syringe pumps are being engineered to be horizontal, which provides greater control over the speed of the syringe driver. As mentioned previously, syringe pumps primary are primarily used for very small amounts of medication – such as pain medication.

The depiction of syringe pump is meant to reflect a Medfusion 3500. Sources:

Infusion pumps, or IV pumps, are invaluable tools in healthcare, and for the past 35 years, AIV has helped biomedical and clinical engineering professionals extend the lives of their infusion pumps by offering:

- End-of-life services for many popular infusion pumps (up to 5 years beyond manufacturer support)

- New and recertified infusion pump replacement parts

- AIV certified infusion pumps - shipped to you patient ready with a 1-year warranty

- Flat and fixed-rate infusion pump repair

- Infusion pump subassembly/mechanism repair

To keep your costs down and maintain your legacy infusion pumps with parts of service, get in touch with AIV here.

Sources:

Infusion Pumps I FDA

Important Considerations for Infusion Pump and Portable Medical Designs

Sunnybrook cancer care website

The Institute for Safe Medication Practices

The National Library of Medicine

About the Author

Laura Collier

Laura Collier has a Bachelor’s Degree in Communications and a Master’s Degree in Business Administration from the University of North Florida. She is the Marketing Manager at AIV, Inc.